• Yichang Adhesive New Material Co.,Ltd.

(China mainland)

• Loyalfre(HK) Co., Ltd.

(China Hongkong )

For more information about the product or our Company.

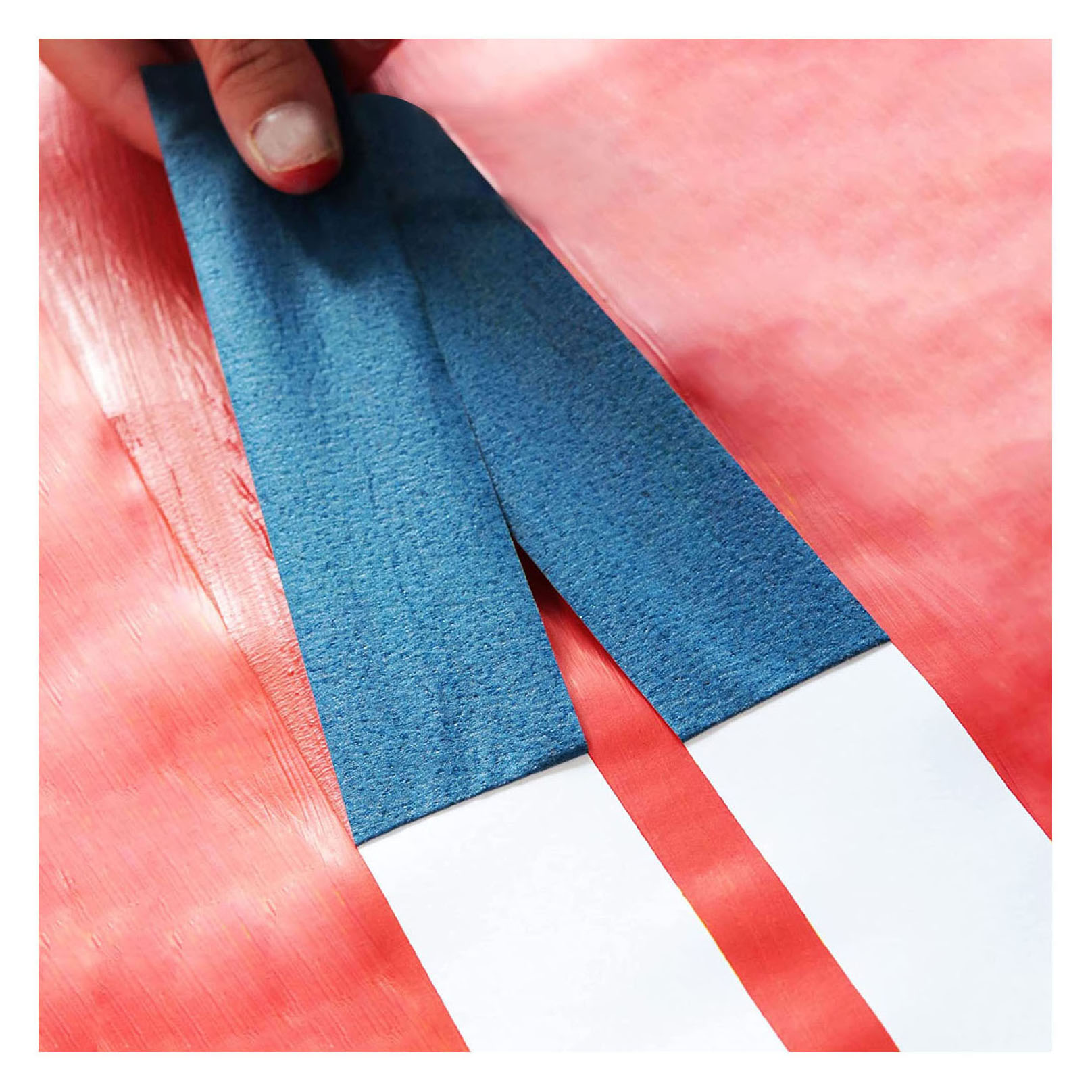

Masking tape is a versatile adhesive tape that is known for its ability to stick to a variety of surfaces. It is made from a paper or thin cloth material and is coated with a pressure-sensitive adhesive. One of the main characteristics of masking tape is its easy removability without leaving behind any residue or damage to the surface it is applied to. This makes it ideal for temporary applications such as painting, where it can be easily peeled off once the task is completed. Additionally, masking tape is known for its ability to conform to irregular surfaces, ensuring a secure bond even on uneven or curved objects.

Another characteristic of masking tape is its ability to be written on. This makes it extremely handy for labeling items or creating temporary signage. Whether it's marking boxes for storage or labeling cables for easy identification, masking tape provides a simple and effective solution. Moreover, masking tape is available in various widths, allowing for flexibility in its usage. From narrow strips for intricate tasks to wide rolls for larger projects, there are options to suit different needs. With its ease of use, versatility, and the absence of residue, masking tape has become a staple tool for DIY enthusiasts, painters, and professionals in various industries.

• Masking tape is known for its easy removability without leaving behind any residue or damage.

• It can conform to irregular surfaces, ensuring a secure bond even on uneven or curved objects.

• Masking tape can be written on, making it useful for labeling items or creating temporary signage.

• It is available in various widths, providing flexibility in its usage for different tasks.

• Masking tape has become a staple tool for DIY enthusiasts, painters, and professionals in various industries.

What are the different types of masking tape available in the market?

1. What is painter's tape and how is it different from regular masking tape?

Painter's tape is a specialized type of masking tape commonly used in painting applications. It is designed to be easily removed without leaving residue or damaging surfaces, making it ideal for creating clean, crisp paint lines. Unlike regular masking tape, which may be more adhesive and leave behind sticky residue, painter's tape offers easier application and clean removal while ensuring professional-looking results.

2. What is high-temperature masking tape used for?

High-temperature masking tape, also known as heat-resistant tape, is specifically engineered to withstand elevated temperatures without degrading or leaving any adhesive residue. It is commonly used in industrial settings for masking during high-temperature processes such as welding, soldering, or powder coating. This type of tape is designed to provide secure masking protection while withstanding heat up to certain temperature limits, ensuring that surfaces and components are shielded from damage or unwanted application of substances.

3. Can I use automotive masking tape for general household painting purposes?

While automotive masking tape shares similarities with regular masking tape, it is typically more durable and resistant to automotive fluids, chemicals, and UV exposure. Due to its enhanced capabilities, it is often recommended for automotive painting and body repair tasks. However, if you are looking for a tape for general household painting purposes, regular masking tape or painter's tape would suffice and offer better adhesion to indoor surfaces.

4. What is the difference between low-tack and high-tack masking tape?

Low-tack masking tape, also known as low-adhesive or low-adhesion tape, is designed to have a weaker adhesive strength compared to regular or high-tack masking tape. It is commonly used when delicate or easily damaged surfaces need to be masked without the risk of leaving adhesive residue or causing surface damage upon removal. On the other hand, high-tack masking tape provides stronger adhesion, making it suitable for applications where a secure bond is essential.

5. Are there waterproof masking tapes available?

Yes, there are waterproof masking tapes available in the market. These tapes are designed to resist water and moisture, making them suitable for outdoor applications or areas prone to moisture exposure. However, it is important to note that the level of water resistance may vary among different brands and types of waterproof masking tape, so it is essential to choose the appropriate tape for your specific needs.

What are the common uses of masking tape in different industries? Masking tape is a versatile tool that finds its applications across various sectors. In the construction industry, it is commonly used to protect surfaces from paint splatters during the painting process. Its adhesive properties allow it to temporarily adhere to surfaces without leaving any residue. It is also used by automotive professionals when conducting detailing work and painting cars, ensuring clean and precise lines while protecting areas that do not require painting.

Does masking tape have uses in the crafting industry? Absolutely! Crafters often turn to masking tape when working on projects that require precision and delicate handling. It serves as a temporary adhesive to hold materials in place, allowing for accurate alignment before permanent bonding. Additionally, its easy tearability makes it convenient for creating straight edges and patterns when painting, stenciling, or scrapbooking. The versatility and affordability of masking tape make it a popular choice for crafters of all levels.

Can electrical tape be used for insulation?

Yes, electrical tape is primarily used for insulation purposes. It is designed to provide an extra layer of protection to electrical wires and connections. Electrical tape is made from materials that have good electrical insulating properties, such as vinyl or rubber, which helps to prevent the risk of electrical shocks and short circuits. It is commonly used in electrical applications to cover exposed wires, secure wire connections, and insulate small cable repairs.

Can electrical tape be used outdoors?

Yes, electrical tape can be used outdoors. However, it is important to ensure that the specific type of electrical tape being used is suitable for outdoor conditions. There are weather-resistant electrical tapes available that are designed to withstand exposure to moisture, UV rays, and other harsh environmental elements. These tapes often have extra adhesive strength and increased durability to ensure long-lasting performance in outdoor applications. It is recommended to check the manufacturer's guidelines and specifications to confirm if the electrical tape is suitable for use outdoors.

What are the key differences between masking tape and electrical tape? While both tapes serve different purposes, their compositions and functionalities set them apart.

Masking tape, commonly made from a thin and flexible paper material, is primarily designed for temporary use. It is designed to be easily removed without leaving any residue or causing damage to the surface it is applied to. Masking tape is commonly used in painting projects, crafting, and even for labeling items. Its adhesive strength is relatively low, which allows for easy removal.

On the other hand, electrical tape is specifically engineered for electrical applications. It is typically made from vinyl or plastic and has a higher adhesive strength compared to masking tape. Electrical tape is heat-resistant, flame-retardant, and provides insulation to protect electrical wires. It is commonly used for splicing wires, insulating electrical connections, and securing cables. Unlike masking tape, electrical tape is designed for long-term usage and is meant to withstand various environmental conditions.

Can masking tape be used as electrical tape? While it may seem like a convenient solution in a pinch, there are potential risks involved in using masking tape as a substitute for electrical tape.

Firstly, it is important to note that masking tape is not specifically designed for electrical applications. It lacks the necessary properties to provide insulation and withstand high temperatures. This means that using masking tape in electrical circuits can pose a serious safety hazard. Without proper insulation, there is a risk of electrical shock or short circuits occurring, which can lead to damage or even fires in electrical systems.

Secondly, masking tape does not have the same level of adhesive strength as electrical tape. It may not adhere securely to wires, connectors, or other electrical components. This can result in the tape becoming loose or unraveling over time, compromising the effectiveness of the electrical insulation. Additionally, the adhesive used in masking tape may not be resistant to moisture or chemicals, further increasing the risk of failure or damage to the electrical connections.

Overall, while masking tape may seem like an easy alternative, it is not recommended for use in electrical applications due to the potential risks it presents. It is crucial to use proper electrical tape that is specifically designed for the purpose to ensure the safety and reliability of your electrical systems.

FAQs (from "People Also Ask"):

1) Can I use masking tape instead of electrical tape?

When considering using masking tape as a substitute for electrical tape, there are a few factors to keep in mind. First and foremost, it is important to understand that electrical tape is specifically designed to handle the unique demands of electrical applications. Masking tape, on the other hand, is mainly intended for general purpose use such as painting or labeling. Given this, the adhesive strength and insulation properties of masking tape may not be sufficient to provide the required electrical safety and reliability. Therefore, carefully evaluate the specific electrical task and the potential risks involved before deciding to use masking tape as a substitute.

2) What are the risks of using masking tape as electrical tape?

Using masking tape in electrical applications carries certain risks that should not be overlooked. One of the primary concerns is the adhesive's capability to withstand high temperatures, especially in situations where electrical wires may generate heat. Masking tape may not have the necessary heat resistance needed to prevent melting or adhesive failure, which can lead to electrical failures, short circuits, or even fires. Additionally, masking tape may not possess the same level of insulation capabilities as electrical tape, making it more vulnerable to electrical arcing or shocks. Therefore, it is crucial to carefully weigh the potential risks and drawbacks before considering the use of masking tape as electrical tape.

What can be used instead of electrical tape?

One common alternative to electrical tape is heat shrink tubing. This tubing provides excellent insulation and can be easily applied to wires. By using heat, the tubing shrinks to form a tight seal around the wire, creating a secure and long-lasting connection. Another alternative is liquid electrical tape, which is a rubberized coating that forms a protective layer around exposed wires. It provides insulation against moisture, chemicals, and corrosion, making it a suitable option for various electrical applications.

Can I use duct tape instead of electrical tape?

While duct tape may seem like a viable option, it is not recommended as a substitute for electrical tape. Duct tape lacks the necessary electrical insulation properties and may pose safety risks. It can easily unravel and lose its adhesive properties when exposed to heat or moisture. Therefore, it is essential to use tape specifically designed for electrical purposes to ensure the safety and reliability of any electrical work.

How to properly apply electrical tape?

When applying electrical tape, it is important to follow proper procedures to ensure effectiveness and safety. Firstly, it is crucial to clean the area where the tape will be applied. This ensures that there is no dirt, debris, or moisture that could potentially interfere with the tape's adhesion. Additionally, it is recommended to stretch the tape while wrapping it around wires or cables, as this helps create a tight and secure bond. It is also advised to overlap the tape by at least half its width, as this provides added protection and prevents exposure of the underlying electrical components. Finally, to ensure a long-lasting and reliable application, it is advisable to smooth out any wrinkles or air bubbles while wrapping the tape, as these imperfections can compromise the effectiveness of the insulation. By following these guidelines, one can ensure the proper application of electrical tape for electrical work.

What are some common mistakes to avoid when applying electrical tape?

When applying electrical tape, there are several common mistakes that should be avoided to promote safety and reliability. One common mistake is using tape that is old, damaged, or expired. It is crucial to use fresh and undamaged tape to ensure proper insulation. Another mistake is not applying enough layers of tape. It is recommended to use multiple layers to provide sufficient insulation and protection. Additionally, it is important not to stretch the tape too tightly, as this can cause it to break or lose its adhesive properties over time. Furthermore, using tape that is not specifically designed for electrical applications should be avoided, as these tapes may not offer the necessary insulation properties. By avoiding these common mistakes, one can ensure the proper application of electrical tape and minimize potential risks.

What tape should I use for electrical work? When it comes to selecting the right tape for electrical work, it is crucial to consider a few factors. Firstly, look for a tape that is specifically designed for electrical applications. Electrical tape is typically made from vinyl material that provides excellent insulation and protection against electrical currents. Furthermore, ensure that the tape has sufficient stretchiness and elasticity to conform to irregular shapes and hold up well over time. Additionally, it is essential to choose a tape that is resistant to heat, moisture, and various chemicals commonly encountered in electrical environments. By taking these factors into account, you can ensure that you select a reliable and durable tape for your electrical projects.

Are there any color coding guidelines for electrical tapes? Yes, color coding is an important aspect of electrical work, as it helps to distinguish between different types of wires and their functions. There are generally accepted color coding guidelines that are followed in many countries. For instance, black electrical tape is often used to indicate insulation, while red indicates a live or active wire. Green or green/yellow tape is commonly used for grounding wires. However, it is important to note that color coding conventions may vary in specific regions, so it is essential to consult local codes and regulations before using color-coded electrical tapes.

Masking tape is lightweight, easy to tear, and has good adhesion properties. It is typically made of paper with a rubber-based adhesive.

There are several types of masking tape, including general-purpose masking tape, high-temperature masking tape, automotive masking tape, and delicate surface masking tape.

Masking tape is widely used in industries such as automotive, painting, construction, and DIY projects.

Electrical tape is specifically designed for electrical applications and is used to insulate and protect electrical wires and connections.

Masking tape is not suitable for electrical work as it does not provide proper insulation. Electrical tape, on the other hand, is designed to withstand electrical currents and provide insulation.

Using masking tape as electrical tape can lead to electrical hazards, such as short circuits, electrical shocks, or fires, as it does not have the necessary insulation properties.

Before considering using masking tape as electrical tape, factors such as voltage, temperature, and safety regulations should be taken into account. However, it is generally not recommended.

Yes, alternatives to electrical tape include heat shrink tubing, wire nuts, and liquid electrical tape. These alternatives provide better insulation and protection for electrical connections.

Electrical tape should be tightly wrapped around the wire or connection, overlapping each layer by half. It should be stretched to activate the adhesive and ensure a secure fit.

When selecting tape for electrical work, consider factors such as insulation properties, temperature resistance, durability, and compatibility with the specific electrical application.

Copyright © 2025 Yitape Co. Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.