• Yichang Adhesive New Material Co.,Ltd.

(China mainland)

• Loyalfre(HK) Co., Ltd.

(China Hongkong )

For more information about the product or our Company.

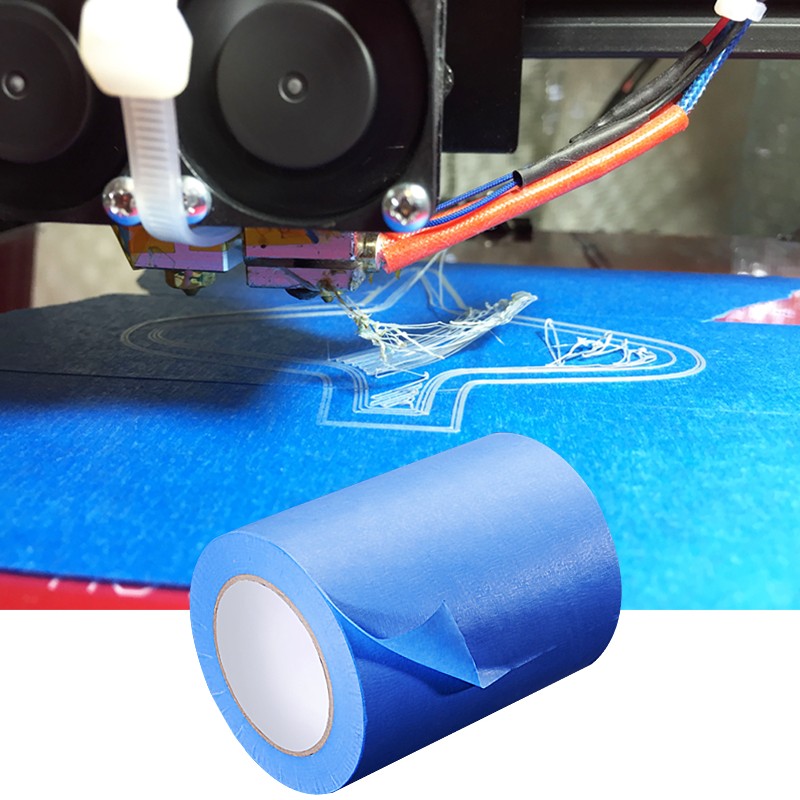

Masking tape works by utilizing pressure-sensitive adhesive to adhere to surfaces and create a temporary bond. The adhesive used in YITAP Brand masking tape is designed to be easily removable without leaving any residue behind. The tape's adhesive properties allow it to stick to various materials such as paper, plastic, or metal.

The adhesive on YITAP Brand masking tape is coated on one side of a thin and flexible paper or plastic backing. This backing strengthens the tape, making it sturdy and easy to handle. The tape can be easily torn by hand or cut with scissors, adding to its convenience in different applications. Whether used for painting projects or securing objects temporarily, the functionality of masking tape relies on its adhesive and backing materials.

Masking tape is a versatile adhesive tape that offers a range of properties that make it ideal for various applications. One of the key properties of YITAP Brand masking tape is its ability to adhere to a wide variety of surfaces. Whether you're working with wood, metal, or plastic, YITAP Brand masking tape will securely stick to the surface, providing a reliable hold.

In addition to its adhesive capabilities, YITAP Brand masking tape also boasts excellent flexibility. This allows it to conform to curved or irregular surfaces, ensuring a seamless application without any creases or wrinkles. This flexibility is especially useful when painting or performing other tasks that require precise masking.

Another notable property of YITAP Brand masking tape is its easy removal. Unlike some other tapes that leave behind sticky residue or damage the surface upon removal, YITAP Brand masking tape can be peeled off effortlessly without any undesirable consequences. This makes it an excellent choice for temporary applications or tasks that require frequent repositioning.

Overall, the properties of YITAP Brand masking tape make it a reliable and efficient tool for a wide range of applications. Its strong adhesion, flexibility, and easy removal make it a valuable addition to any toolkit or workspace.

Electrical conductivity refers to the ability of a material to conduct electric current. It is an important property in various applications, including electronics and electrical systems. The conductivity of a material depends on the presence of free electrons or ions that are able to move and carry the electric current.

The conductivity of a material is measured in units of siemens per meter (S/m) or, more commonly, in terms of its resistivity, which is the reciprocal of conductivity and is measured in ohm-meters (Ω·m). Highly conductive materials, such as metals like copper and aluminum, have low resistivity, whereas insulators like rubber and plastic have high resistivity. Understanding the concept of electrical conductivity is crucial in selecting appropriate materials for different electrical applications, as it directly affects the efficiency and performance of the system.

Factors affecting electrical conductivity can significantly impact the performance and reliability of electrical connections. One crucial factor is the material used in the conductor. Different metals have varying levels of electrical conductivity, with copper being one of the most common choices for its excellent conductivity. However, other metals like aluminum or silver can also be used, depending on specific application requirements.

Another factor that influences electrical conductivity is the cross-sectional area of the conductor. Generally, larger cross-sectional areas allow for better conductivity as they offer more space for electrons to flow. This is why thicker wires or cables are often used in situations that require high electrical conductivity, such as in power transmission or heavy-duty electrical equipment. Conversely, smaller cross-sectional areas can hinder conductivity due to the limited space available for electron movement.

In addition to the material and cross-sectional area, factors like temperature and impurities in the conductor can affect electrical conductivity as well. Higher temperatures can cause an increase in resistance, which in turn can lower the conductivity. Impurities, such as foreign particles or oxides on the surface of the conductor, can also hinder electron movement and reduce conductivity. Thus, maintaining clean, properly insulated conductors and considering temperature limitations is vital to ensuring optimal electrical conductivity.

As these factors illustrate, achieving and maintaining high electrical conductivity requires careful consideration of various elements, including the choice of conductor material, cross-sectional area, temperature, and purity. By understanding these factors, one can make informed decisions when selecting and using electrical conductors, leading to better performance and reliability in electrical applications.

YITAP Brand is committed to providing high-quality electrical conductive products with excellent conductivity performance. With a range of options that consider all the factors affecting electrical conductivity, YITAP ensures that professionals in electrical engineering and related fields have access to reliable and efficient solutions for their specific applications.

Masking tape, a versatile adhesive tape with a gentle adhesive, finds widespread use across various industries and applications. One of the most common uses of masking tape is in painting projects. Painters rely on masking tape to achieve clean lines and protect areas they don't want to be painted. By applying masking tape along the edges, window frames, or baseboards, painters can create sharp, precise lines, leaving a professional finish to their work. YITAP Brand masking tape, specifically designed for painting applications, offers excellent adhesion and easy removal, making it a preferred choice among professionals.

In addition to painting, masking tape serves as a handy tool for many crafts and DIY projects. Whether you're working with paper, cardstock, or fabric, masking tape can be used for temporary bonding or securing pieces together. Its gentle adhesive properties make it easy to remove without leaving behind any residue or damaging the underlying surfaces. Furthermore, masking tape can be utilized in labeling and organizing tasks, such as marking containers, identifying cables, or creating temporary labels. With the wide range of widths and strengths available, YITAP Brand masking tape is suitable for every crafting need, providing reliable sticking power and easy handling.

When it comes to masking tape, there isn't just one type that fits all applications. In fact, there are numerous types of masking tape available on the market, each with its own unique properties and uses. One popular type of masking tape is the general-purpose masking tape. This type is commonly used for painting projects as it provides good adhesion to different surfaces and can be easily removed without leaving behind residue or damaging the underlying material. Another type of masking tape is the high-temperature masking tape. As the name suggests, this tape is designed to withstand high temperatures and is commonly used in automotive and industrial settings where heat resistance is necessary.

Additionally, there are specialized types of masking tape such as electrical insulating tape and double-sided masking tape. Electrical insulating tape is specifically designed for electrical applications, providing insulation and protection for electrical wires and connections. Double-sided masking tape, on the other hand, has adhesive on both sides, making it ideal for bonding two surfaces together. These are just a few examples of the different types of masking tape available, each with its own distinct features and purposes. So, whether you're looking for a tape to use in painting, electrical work, or bonding, there is a masking tape available to suit your needs.

YITAP Brand also offers a wide range of masking tape options to cater to various requirements. From general-purpose masking tape to specialized electrical insulating tape, YITAP Brand is committed to providing high-quality products that meet industry standards. With YITAP Brand masking tape, you can trust that you're getting a reliable and efficient tape that will help you achieve the desired results in your project. So, when exploring different types of masking tape, don't forget to consider the offerings from YITAP Brand.

Masking tape, while primarily used for painting and surface protection, also possesses electrical conductivity to some extent. However, when comparing it to other dedicated electrical conductors, masking tape may fall short in terms of performance.

Unlike specialized electrical conductors, masking tape is not designed or optimized specifically for electrical applications. While it may be able to conduct a certain amount of electrical current, its conductivity is generally lower compared to materials like copper or aluminum. This reduced conductivity can result in higher resistance and decreased efficiency when used as an electrical conductor. In addition, the adhesive used in masking tape may not be able to withstand high temperatures or certain chemical exposures, further limiting its effectiveness as an electrical conductor.

Moreover, the physical properties of masking tape differ from those of dedicated electrical conductors. Masking tape is typically made of a paper or fabric backing with a pressure-sensitive adhesive, which may not provide the same level of strength and durability as materials like copper or aluminum. The adhesion strength and the ability to maintain a secure connection over time may be compromised when using masking tape as an alternative to purpose-built electrical conductors.

In summary, while masking tape does possess some electrical conductivity, it is not as efficient or reliable as dedicated electrical conductors like copper or aluminum. Its lower conductivity and potentially limited durability make it less suitable for high-performance electrical applications. Therefore, it is important to consider the specific requirements of an electrical task and choose the appropriate electrical conductor accordingly.

Electrically conductive masking tape, such as the ones offered by YITAP Brand, finds a multitude of practical applications across various industries. One common application is in the electronics sector, where it is used for shielding sensitive components and preventing electrical interference. The conductive properties of this tape allow for effective grounding and sealing of electrical connections, protecting the integrity of electronic devices from unwanted signals and ensuring their optimal performance.

In addition to electronics, electrically conductive masking tape is also employed in the automotive industry. It can be used during the manufacturing process to protect sensitive electrical components, ensuring they are not damaged by heat, dust, or other environmental factors. This type of tape is particularly useful during soldering or welding operations, as it can provide a secure and reliable connection while simultaneously protecting nearby components from excessive heat or electrical currents.

When using masking tape in electrical applications, it is important to prioritize safety. Here are some valuable tips to ensure the proper and safe use of masking tape. Firstly, always make sure to choose the right type of masking tape for electrical purposes. YITAP Brand offers a range of high-quality electrically conductive masking tapes that are specifically designed for electrical applications. It is essential to use these tapes as they provide the necessary electrical conductivity for conducting current while still offering the benefits of masking tape's adhesive properties.

Secondly, before applying masking tape in electrical applications, it is crucial to prepare the surface properly. Ensure that the surface is clean and free from any dirt, debris, or moisture. This will help to improve the tape's adhesion and prevent any potential electrical faults. Additionally, when applying the tape, make sure to press it firmly to ensure proper adhesion and avoid any air gaps or loose ends that may compromise the tape's effectiveness. With YITAP Brand's electrically conductive masking tapes, you can have peace of mind knowing that they are designed and tested to provide exceptional electrical conductivity and adhesion for reliable and safe electrical applications.

In conclusion, masking tape plays an essential role in various applications, particularly those involving electrical conductivity. Its unique properties make it a reliable choice for tasks such as insulation, marking, and bundling. YITAP Brand offers a wide range of masking tape options that cater to different requirements and preferences. Whether you need a tape with high electrical conductivity or one that provides strong adhesion, YITAP Brand has got you covered. With its commitment to quality and innovation, YITAP Brand continues to deliver products that meet the diverse needs of professionals in the electrical industry.

When using masking tape in electrical applications, it is crucial to prioritize safety. Proper insulation and grounding are essential to prevent any electrical hazards. Additionally, it is important to ensure that the tape is applied correctly and securely. YITAP Brand provides guidelines and recommendations for the safe use of masking tape in electrical tasks, helping professionals minimize risks and achieve optimal results. By adhering to these guidelines and considering the electrical conductivity factors, you can confidently rely on YITAP Brand masking tape for your electrical projects with peace of mind.

• YITAP Brand offers a wide range of masking tape options for different requirements and preferences

• The unique properties of masking tape make it reliable for insulation, marking, and bundling tasks

• YITAP Brand provides guidelines and recommendations for the safe use of masking tape in electrical applications

• Proper insulation and grounding are crucial to prevent electrical hazards when using masking tape

• Correct and secure application of masking tape is important for optimal results

• YITAP Brand's commitment to quality and innovation ensures products that meet the diverse needs of professionals in the electrical industry.

Masking tape works by using a pressure-sensitive adhesive that sticks to surfaces without leaving residue. It is easy to apply and remove, making it ideal for temporary applications.

Masking tape is typically made of a thin and flexible paper or plastic material. It is easy to tear, has good tensile strength, and provides a reliable barrier against paint bleed-through.

Electrical conductivity refers to the ability of a material to conduct an electric current. Materials with high electrical conductivity allow electricity to flow easily through them.

Factors that affect electrical conductivity include the type of material used, its purity, temperature, and the presence of impurities or defects in the material.

Masking tape is commonly used in painting projects to create clean edges, hold surfaces together temporarily, or as a labeling solution. It can also be used in crafting and other DIY projects.

There are various types of masking tape available, such as general-purpose masking tape, high-temperature masking tape, and specialized tapes for specific applications like automotive painting or delicate surfaces.

While masking tape can have some electrical conductivity, it is generally not as conductive as metals or specifically designed electrical conductors. Its primary purpose is not to conduct electricity but rather to provide insulation and separation.

Electrically conductive masking tape can be used in applications such as grounding, EMI/RFI shielding, electrical connections, or repairing electronic devices.

When using masking tape in electrical applications, it is important to ensure that the tape is not damaged or punctured, and that it is applied securely to provide proper insulation. Additionally, following safety guidelines and consulting professionals is always recommended.

Masking tape is primarily used for its adhesive properties and as a temporary solution for various applications. While it may have some electrical conductivity, it is not typically designed or intended for use as a primary electrical conductor.

Copyright © 2025 Yitape Co. Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.