• Yichang Adhesive New Material Co.,Ltd.

(China mainland)

• Loyalfre(HK) Co., Ltd.

(China Hongkong )

For more information about the product or our Company.

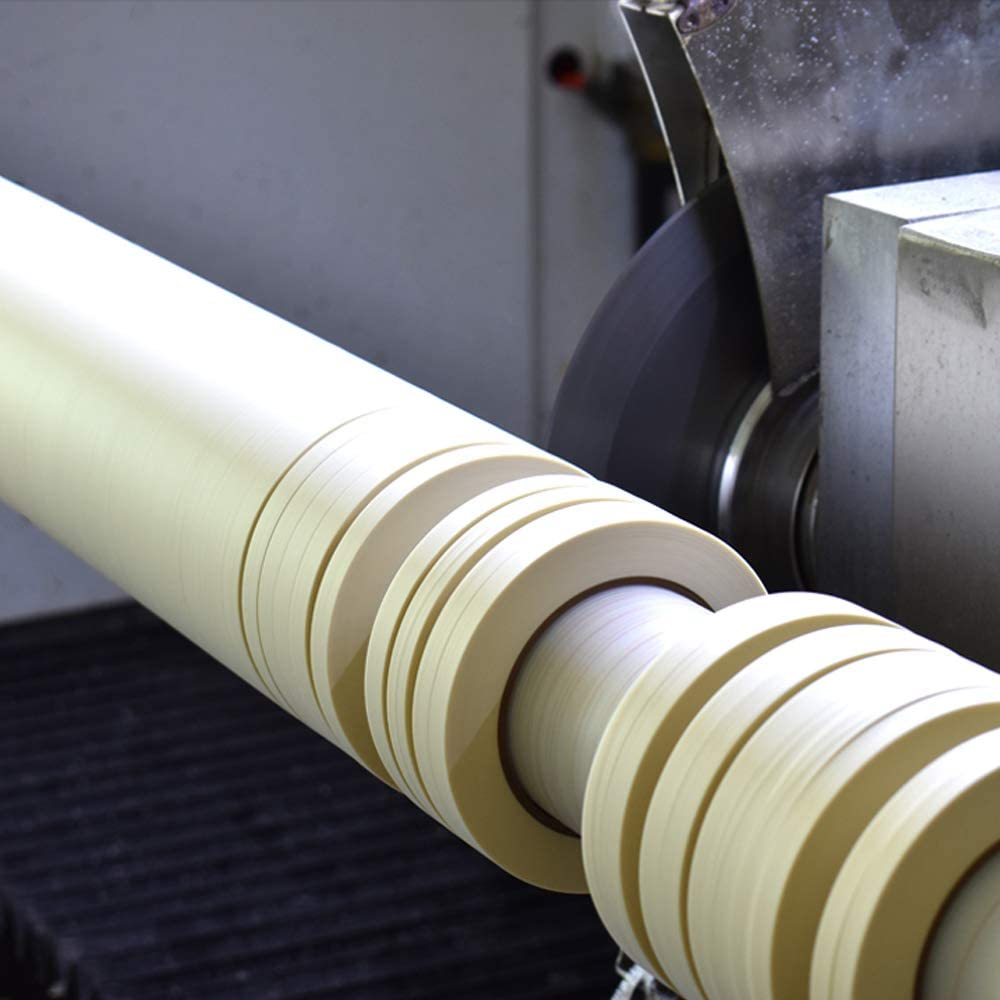

Masking tape is a type of adhesive tape that is commonly used in various industries and household applications. It is made of a thin and flexible paper or plastic backing, coated with a pressure-sensitive adhesive on one side. The adhesive used in masking tape is designed to be easily removable without leaving residue or damaging the surface it is applied on. This makes it a versatile tool for temporary bonding and masking purposes.

YITAP Brand masking tape is known for its high-quality adhesion and performance. It is available in different widths and lengths to suit various needs. The tape can easily be torn by hand, making it convenient to use without the need for additional tools. It is designed to be used on a wide range of surfaces such as wood, metal, glass, and paper. Whether for painting projects, crafting, or simple everyday tasks, YITAP Brand masking tape provides reliable adhesion and easy removal, making it a must-have tool for professionals and DIY enthusiasts alike.

Masking tape is a versatile adhesive tape that is known for its unique properties. One of the key properties of masking tape is its adhesive backing, which allows it to stick firmly onto surfaces without damaging them or leaving behind any residue. YITAP Brand masking tape, in particular, is designed with a high-quality adhesive that ensures long-lasting hold and clean removal.

Besides its adhesive properties, masking tape also possesses excellent flexibility. It can be easily torn by hand, making it convenient to use in various applications. This flexibility allows users to easily mold and shape the tape around irregular surfaces or corners. Additionally, masking tape is available in different widths, which further adds to its versatility. YITAP Brand offers a wide range of masking tape sizes, allowing users to choose the most suitable option for their specific needs.

Masking tape is a versatile adhesive tape that is widely used in various applications. It is composed of a thin strip of paper or fabric, coated with a pressure-sensitive adhesive on one side. The adhesive is typically made from a combination of natural rubber or synthetic materials, ensuring strong and reliable adhesion.

When applied, masking tape works by adhering to the surface it is applied to, creating a temporary bond. It forms a barrier that prevents paint, varnish, or other substances from seeping through or reaching the areas that need to be protected. The adhesive on the tape is designed to be easily removable, allowing for clean and damage-free removal after use. This property makes masking tape ideal for temporary purposes, such as painting, packaging, labeling, or art projects.

The effectiveness of masking tape is dependent on its adhesive properties and the surface it is applied to. The adhesive creates a bond with the surface, allowing the tape to stick firmly and remain in place until it is intentionally removed. This temporary bond is strong enough to resist minor movements and vibrations but can be easily peeled off without leaving residue or causing damage. The precise manufacturing techniques and materials used in creating masking tape ensure its consistent performance and reliability, making it a staple in various industries and everyday tasks.

Masking tape is a versatile adhesive product that finds a wide range of uses in various industries and everyday household tasks. One common use of masking tape is in painting projects. Whether you are a professional painter or a DIY enthusiast, masking tape is an essential tool for creating clean, straight lines and protecting surfaces that you don't want to be painted. It can be easily applied and removed without leaving any residue or damaging the underlying surface, making it the go-to choice for many painters.

Additionally, masking tape is widely used in crafting and art projects. Its ability to adhere to different surfaces, such as paper, fabric, and wood, allows artists and crafters to create intricate designs and patterns. Whether it's creating borders, cutting stencils, or securing materials in place, masking tape provides a reliable and temporary solution for various artistic endeavors. The YITAP Brand of masking tape is known for its high-quality adhesive properties and durability, making it a trusted choice for professionals and hobbyists alike.

Masking tape is a versatile adhesive tape commonly used in various applications, but can it withstand high temperatures? The answer depends on the specific type of masking tape. While standard masking tape may not be able to withstand extreme heat, there are heat-resistant masking tapes available that are specifically designed to handle high temperatures.

YITAP Brand, a leading manufacturer in the adhesive tape industry, offers a range of heat-resistant masking tapes that can withstand elevated temperatures. These tapes are made with special materials and can typically endure temperatures up to a certain threshold, such as 300 degrees Fahrenheit (150 degrees Celsius) or even higher in some cases. It is important to note that different heat-resistant masking tapes have varying temperature limits, so it is crucial to choose the tape that suits your specific needs and requirements.

- YITAP Brand offers a range of heat-resistant masking tapes

- These tapes are made with special materials

- Can withstand temperatures up to 300 degrees Fahrenheit or higher in some cases

- Different heat-resistant masking tapes have varying temperature limits

Masking tape is a versatile adhesive tape widely used in various industries and applications, but its performance can be affected by heat. When exposed to high temperatures, masking tape can undergo changes in its physical and chemical properties. The adhesive used in masking tape is typically made from rubber or acrylic, both of which have different heat tolerances.

Rubber-based masking tapes often have a lower heat resistance compared to their acrylic counterparts. As the temperature rises, the rubber adhesive can soften and lose its stickiness, making the tape less effective at adhering to surfaces. In contrast, acrylic-based masking tapes are designed to withstand higher temperatures, retaining their adhesive strength and overall performance. However, prolonged exposure to extreme heat can still cause the adhesive to deteriorate and reduce the tape's effectiveness. Therefore, it is crucial to consider the heat resistance of masking tape when choosing the right product for specific applications.

When selecting heat-resistant masking tape, there are several important factors to consider. First and foremost, it is crucial to evaluate the temperature range that the tape can withstand. Different applications may require varying levels of heat resistance, so it is essential to choose a tape that can handle the specific temperatures involved. Additionally, the duration of exposure to heat should be taken into account, as some tapes may withstand short bursts of high temperatures, while others are designed for long-term heat resistance. Our brand, YITAP, offers a range of heat-resistant masking tapes that are carefully engineered to withstand various temperature ranges and durations, providing reliable performance in demanding heat applications.

In addition to temperature resistance, it is important to consider the adhesive properties of the masking tape. The adhesive should be strong enough to securely hold the tape in place, even under high temperatures. It is also essential to ensure that the adhesive does not leave any residue or damage the surface upon removal. YITAP Brand, known for its commitment to quality and innovation, offers heat-resistant masking tapes with specially formulated adhesives that provide excellent bonding strength without causing any damage. By considering both the temperature resistance and adhesive properties, you can select the most suitable heat-resistant masking tape for your specific application.

When it comes to alternatives to heat-resistant masking tape, there are a few options that can be considered. One popular alternative is aluminum foil tape. This type of tape is made from a thin layer of aluminum, making it highly resistant to heat. It is commonly used in HVAC systems and other applications where high temperatures are present. Aluminum foil tape also has excellent adhesive properties, ensuring a secure bond on various surfaces.

Another alternative to heat-resistant masking tape is Kapton tape. Kapton tape is a polyimide film tape that is known for its ability to withstand extreme temperatures. It is commonly used in electronics and aerospace industries, where heat insulation and protection are crucial. Kapton tape also has excellent electrical insulation properties, making it a versatile option for applications that require high temperature resistance.

Heat-resistant masking tape is a versatile adhesive that is specifically designed to withstand high temperatures. When using heat-resistant masking tape from YITAP Brand, it is important to follow the proper application techniques to ensure optimal performance.

First, make sure the surface where the tape will be applied is clean and dry. Any dirt, dust, or debris can affect the adhesive strength of the tape. Use a mild cleaning solution if necessary, but ensure that the surface is completely dry before proceeding. Next, cut the required length of tape using a sharp pair of scissors or a utility knife. It is advisable to cut the tape slightly longer than needed to allow for better handling during application. When applying the tape, firmly press it onto the surface, ensuring that there are no air bubbles or wrinkles. The strong adhesive of the heat-resistant masking tape from YITAP Brand will ensure a secure bond. For best results, apply the tape in one continuous motion rather than in small sections. Once applied, gently press down on the tape to ensure proper adhesion.

When removing the tape, do so carefully and slowly to avoid damaging the surface. Start by pulling the tape at a 45-degree angle, away from the surface. This will help prevent any tearing or residue from being left behind. If any residue is left on the surface, it can usually be easily removed with a mild solvent or adhesive remover. Remember to follow the instructions provided by YITAP Brand for proper use and disposal of the heat-resistant masking tape.

Proper storage and maintenance of heat-resistant masking tape is crucial to ensure its longevity and effectiveness in various applications. To maximize the lifespan of your YITAP brand heat-resistant masking tape, it is recommended to store it in a cool and dry environment. Excessive heat and humidity can deteriorate the adhesive properties of the tape, leading to reduced performance.

When storing the tape, make sure to keep it away from direct sunlight and sources of heat, such as radiators or heaters. Additionally, maintaining the adhesive side free from dust, dirt, and oils is essential for optimal adhesion. Clean the surface where the tape will be applied using a mild detergent or rubbing alcohol, and then make sure it is completely dry before applying the tape.

Regularly inspecting the tape for any signs of deterioration or damage is also important. If you notice any discoloration, loss of adhesion, or cracks on the tape, it is advisable to replace it with a fresh roll. By following these simple tips for storing and maintaining heat-resistant masking tape, you can ensure its reliability and performance when used for high-temperature applications.

Masking tape is a type of adhesive tape that is designed to be easily removed without leaving any residue or damaging the surface it was applied to.

Masking tape is typically made of paper or a thin, flexible film, and it is coated with an adhesive that allows it to stick to surfaces. It is easy to tear by hand and can conform to curved or irregular surfaces.

Masking tape works by adhering to a surface and creating a barrier that prevents paint, stains, or other substances from reaching areas that need to be protected. It can be easily removed once the task is complete.

Masking tape is commonly used in painting projects to create clean lines and protect surfaces from paint drips or overspray. It is also used for packaging, labeling, and holding objects together temporarily.

Regular masking tape is not designed to withstand high temperatures. However, there are heat-resistant masking tapes available that can withstand elevated temperatures without melting or losing their adhesive properties.

Heat can cause regular masking tape to melt or lose its adhesive properties, which can result in the tape peeling off or leaving residue behind. Heat-resistant masking tape is specifically designed to withstand high temperatures without these issues.

When choosing heat-resistant masking tape, it is important to consider the temperature range it can withstand, the type of surface it will be applied to, and the duration of the heat exposure.

Some alternatives to heat-resistant masking tape include aluminum foil, high-temperature tapes, or specialty tapes designed for specific applications such as electrical insulation.

To properly use heat-resistant masking tape, make sure the surface is clean and dry before applying the tape. Press the tape firmly onto the surface to ensure good adhesion. When removing the tape, do it slowly and at a low angle to minimize the risk of residue or damage.

To store heat-resistant masking tape properly, keep it in a cool, dry place away from direct sunlight or heat sources. Avoid exposing the tape to extreme temperatures or humidity. Make sure the roll is securely sealed after each use to prevent dust or debris from contaminating the adhesive.

Copyright © 2025 Yitape Co. Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.