• Aluminum backing provides excellent reflection of both heat and light.

• High quality adhesive with strong adhesion and holding power offers permanent sealing and bonding on Foil-Scrim-Kraft Facing joints and seams in HVAC ductwork application.

• Good aging resistance both indoors and outdoors.

• Low moisture vapor transmission rate offers excellent sealing and patching performance.

PROPERTIES | METRIC | ENGLISH | TEST METHOD |

Backing Thickness | 22 Micron | 0.88 Mil | PSTC-133 / ASTM D 3652 |

Total Thickness | 55 Micron | 2.20 Mil | PSTC-133 / ASTM D 3652 |

Adhesion to Steel | 18 N/25mm | 65 Oz./In. | PSTC-101 / ASTM D 3330 |

Tensile Strength | 40 N/25mm | 9.1 Lb/In | PSTC-131 / ASTM D 3759 |

Elongation | 3.0 % | 3.0 % | PSTC-131 / ASTM D 3759 |

Service Temperature | -20 ~ +80 °C | -4 ~ +176 °F | ------------ |

Applying Temperature | +10 ~ 40 °C | +50 ~ +105 °F | ------------ |

Five types of aluminum tape :

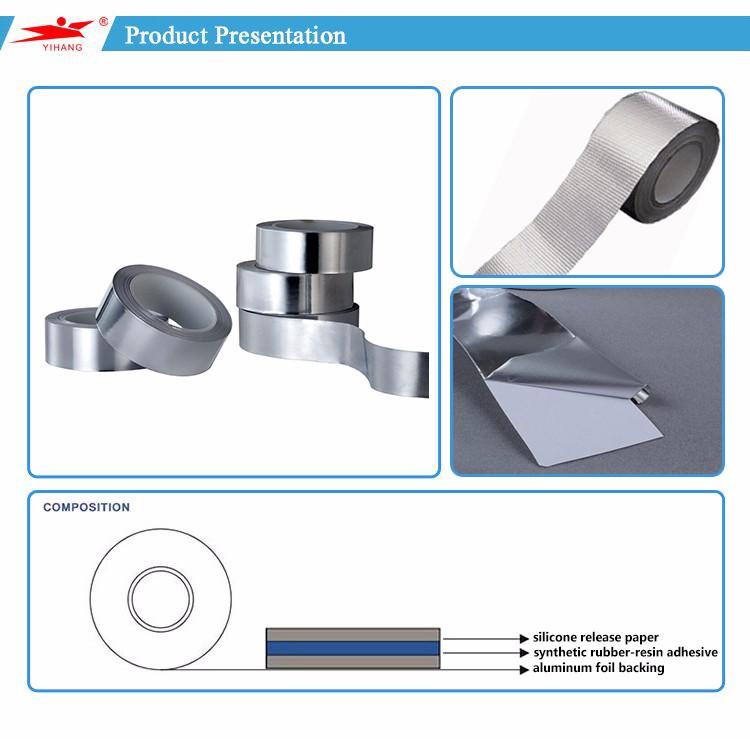

A. Aluminum tape with synthetic rubber-resin adhesive, protected by an easy-release silicone release paper.

B. Aluminum tape with solvent acrylic adhesive, protected by an easy-release silicone release paper.

C. Aluminum tape with cold weather acrylic adhesive, protected by an easy-release silicone release paper.

D. Aluminum tape with clod weather solvent acrylic adhesive, protected by an easy-release silicone release paper.

E. Aluminum tape with flame retardant cold weather solvent acrylic adhesive, protected by an easy-release silicone release paper.

F.Aluminum tape with transparent high performance synthetic rubber-resin adhesive.

G.Aluminum tape with flame retardant solvent acrylic adhesive.

TYPICAL APPLICATIONS: HVAC industry for joining and sealing Foil-Scrim-Kraft Facing laminated fiberglass blanket / duct board joints and seams; joining and sealing flexible air duct seams and connections. General purpose holding, patching, sealing and masking applications – indoors and outdoors.

3M 1181 Tape consists of a 1-ounce deadsoft copper foil backing and a unique electrically conductive pressure-sensitive acrylic adhesive.

Like all 3M shielding tapes, 3M 1181 is available in standard and custom widths and lengths. Standard length is 18 yards.

Many factors determine the true shielding effectiveness of a shielding tape, including type and thickness of foil, adhesive type, intimacy of contact, smoothness of application surface, strength and frequency of the EMI signal, etc. However, using standard tests and fixtures, it is possible to determine avalue for the attenuation.For 3M 1181 Tape, typical shielding effectiveness (far field) is in the range of 60dB to 80dB (30 MHz to 1 GHz).

Copyright © 2025 Yitape Co. Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.